Andy Visser

24 May 2019: The University of Canberra’s WORKSHOP7 is a new workspace that provides Faculty of Arts and Design students with a state-of-the-art facility to enable them to push the limits of their creative pursuits.

Each student’s design process is fully supported through purpose-built spaces which include a 3D printing pod, laser cutter lab, Computer Numerical Control (CNC) machining room, electronics lab and a composites manufacturing lab.

Being part of the first cohort of design students to make use of UC’s new facility, this year’s second- and third-year industrial design students have stretched their creative boundaries.

So, what do a beehive, origami and sea-urchin have in common? They were the inspiration for some third-year industrial design students’ responses to their assignment brief to design and manufacture a market-ready piece of foldable furniture.

Getting into the nuts, bolts and hinges of the matter, the industrial design students presented a broad range of creative and workable solutions. These final designs utilised a diverse set of material choices and production techniques to address the challenges of comfortably furnishing smaller living spaces.

It was evident that the students spent copious amounts of time in WORKSHOP7 this semester working on various prototypes of their designs before producing the final ‘product’ that was ready for expert evaluation.

Adjudicating their work was a panel of highly regarded industrial design experts and UC alumni that provided invaluable feedback and advice to each student. The panel included Mr Sam Tomkins Lecturer in Design, UC Emeritus Professor Bill Green, Mr Dan Armstrong (Director of Formswell Design), Mr Tom Skeehan (Designer and Director of Skeehan Studio) and Ryan Robinette (designer and maker).

“The student showcase brought to light exceptional design capabilities and provoked robust evaluation and discussion. They demonstrated outstanding creative thought processes and developed workable solutions that in some cases could potentially be taken to market,” said Mr Skeehan.

“With a few tweaks and possible adjustments here and there for those who would like to see their design in production the potential is enormous.”

“I loved working in the new workshop. It made for a much smoother process and I was able to see my design come to life through better planning and access to tools and machinery that compares with some of the best that we could access in the workplace,” said Oliver Chiswell, third-year industrial design student.

Second-year industrial design students were tasked with developing a restaurant cutlery collection in response to the rapidly changing culture of eating. These ‘eating tools’ would need to stand the test of time to remain relevant until the year 2119.

The second-year students’ work was equally creative. The panel of adjudicators included UC’s Mr Sam Tomkins, Ms Erin Hinton Associate Dean Education for the Faculty of Arts and Design and Mr Bernd Bradmann Head Chef of Boffins.

“The creativity and depth of thinking around the relevance of their collection to people living beyond their lifetime were beyond inspiring,” said Mr Bradmann.

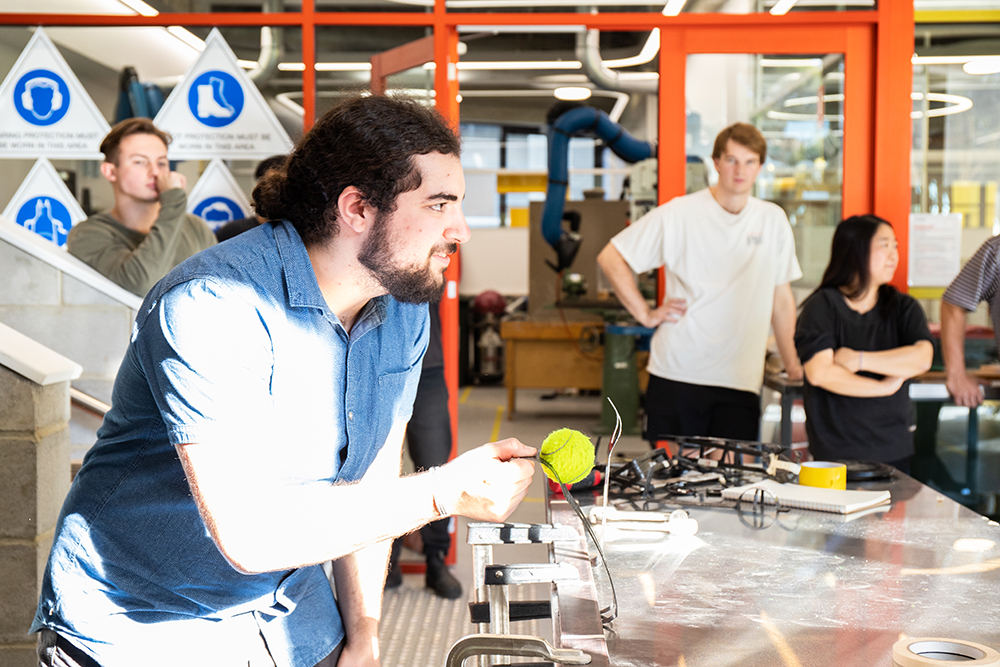

Design students who completed their industrial design technology unit, Materials and Processes Advanced, were asked to apply their knowledge gained from a series of lectures on composite materials to design a catapult made from carbon fibre composite materials.

The catapult had to weigh no more than 20 grams with the aim of flinging a standard 55-gram tennis ball more than two meters. The catapult that propelled the tennis ball the furthest and had the best power to weight ratio would be the winner.

WORKSHOP7’s composites laboratory was a hive of activity for a few weeks as the students set their sights on the prize and started to build their composite catapults.

The large open assembly area in WORKSHOP7 proved to be the ideal location for testing the catapults on submission day. Each student’s catapult successfully propelled the tennis ball past the two metre mark with the average distance being around five metres.

It was, however, the catapult designed by third-year industrial design student Katie McAuliffe that demonstrated the best power to weight ratio after the tennis ball propelled from her catapult covered a distance of 15 metres, making her design the notable winner.

“The catapult project showcased the design students’ abilities to apply the design process, think laterally and conceive innovative, creative and novel solutions to a design problem,” said Bill Shelley Technical Services Coordinator from the Faculty of Arts and Design.

“The quality of the work presented this semester far exceeded our expectations. Last year these students were producing outstanding work in our old workshop; but the calibre of work presented this semester achieved new levels of excellence,” said Mr Tomkins.

“The future looks bright from here with the new technology and additional support and guidance available to students in WORKSHOP7.”

Photos by Byron Carr